|

| ㆍ작성일 |

2003-02-18 |

| ㆍ첨부#2 |

1045532862.bmp

(0KB) (Down:3) 1045532862.bmp

(0KB) (Down:3)

|

| ㆍ응용분야 | 전기전자, 기계, 화학 |

|

ㆍ추천: 0 ㆍ조회: 1139

|

|

|

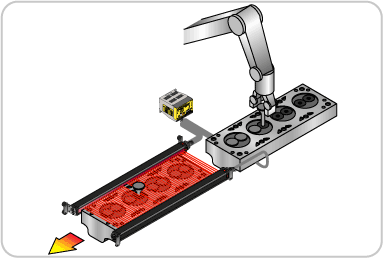

MINI-ARRAY Engine Valve Stem Detection

MINI-ARRAY Engine Valve Stem Detection

Valves do not always drop down into place into the engine head. Valve stems measure 5 mm (0.2”) diameter, which are easily detected with the 2.5 mm (0.1”) resolution of the High-resolution MINI-ARRAY system.

Objective:

To detect unseated valves in an automated engine assembly process.

Sensor Models:

High-resolution MINI-ARRAY system

자료출처 : BANNER

|

| 번호 |

|

글 제 목 |

응용분야 |

작성일 |

조회 |

|

310 |

|

PresencePLUS Correct Assembly Of Metal Container PresencePLUS Correct Assembly Of Metal Container

|

전기전자, 기계, 화학

|

2003-02-19

|

1024

|

|

|

309 |

|

PresencePLUS Control Knob Stem Inspection PresencePLUS Control Knob Stem Inspection

|

전기전자, 기계, 화학

|

2003-02-18

|

1086

|

|

|

308 |

|

PresencePLUS Ceramic Ring Orientation PresencePLUS Ceramic Ring Orientation

|

전기전자, 기계, 화학

|

2003-02-18

|

1131

|

|

|

307 |

|

PICO-AMP Loop Control PICO-AMP Loop Control

|

전기전자, 기계, 화학

|

2003-02-18

|

1153

|

|

|

306 |

|

OMNI-BEAM Full Case Inspection OMNI-BEAM Full Case Inspection

|

전기전자, 기계, 화학

|

2003-02-18

|

1269

|

|

|

305 |

|

OMNI-BEAM Cable Jacket Flaw Detection OMNI-BEAM Cable Jacket Flaw Detection

|

전기전자, 기계, 화학

|

2003-02-18

|

1231

|

|

|

304 |

|

MINI-BEAM Can Caps Inspection MINI-BEAM Can Caps Inspection

|

전기전자, 기계, 화학

|

2003-02-18

|

1293

|

|

|

303 |

|

MINI-BEAM Expert Printed Circuit Board Registration MINI-BEAM Expert Printed Circuit Board Registration

|

전기전자, 기계, 화학

|

2003-02-18

|

1344

|

|

|

302 |

|

MINI-ARRAY Hole Pattern Inspection MINI-ARRAY Hole Pattern Inspection

|

전기전자, 기계, 화학

|

2003-02-18

|

1261

|

|

|

301 |

|

MINI-ARRAY High Resolution High Pin Detection MINI-ARRAY High Resolution High Pin Detection

|

전기전자, 기계, 화학

|

2003-02-18

|

1208

|

|

|

300 |

|

MINI-ARRAY Engine Valve Stem Detection MINI-ARRAY Engine Valve Stem Detection

|

전기전자, 기계, 화학

|

2003-02-18

|

1139

|

|

11

|

|

센서허브넷 소개

센서허브넷 소개  Sitemap

Sitemap