|

| ㆍ작성일 |

2003-02-19 |

| ㆍ첨부#2 |

1045617617.bmp

(0KB) (Down:4) 1045617617.bmp

(0KB) (Down:4)

|

| ㆍ응용분야 | 전기전자, 기계, 화학 |

|

ㆍ추천: 0 ㆍ조회: 1132

|

|

|

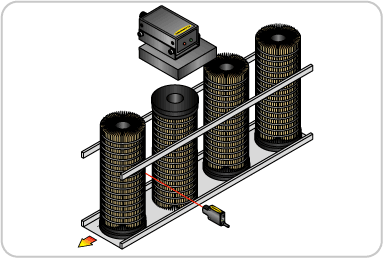

PresencePLUS Filter Orientation Check

PresencePLUS Filter Orientation Check

The PresencePLUS sensor checks each filter assembly to be sure the uncapped end is in the up position. The end caps are molded black plastic. A filter assembly with the end cap in the up position returns no light to the sensor, and is rejected. A filter in the correct position registeres a high white pixel count. This application uses an 8-millimeter lens. Sensing distance is 230 mm (9”).

Objective:

To check for the proper orientation of a filter assembly, before the second end cap is attached.

Sensor Models:

PresencePLUS P1B65Q, LEDRA140 LED ring light, MINI-BEAM 2 QS126E and QS12VN6R

자료출처 : BANNER

|

| 번호 |

|

글 제 목 |

응용분야 |

작성일 |

조회 |

|

321 |

|

PresencePLUS Metal Flash Inspection PresencePLUS Metal Flash Inspection

|

전기전자, 기계, 화학

|

2003-02-20

|

993

|

|

|

320 |

|

PresencePLUS Lot Code Presence Inspection PresencePLUS Lot Code Presence Inspection

|

전기전자, 기계, 화학

|

2003-02-20

|

1159

|

|

|

319 |

|

PresencePLUS Light Bulb Base Inspection PresencePLUS Light Bulb Base Inspection

|

전기전자, 기계, 화학

|

2003-02-19

|

1024

|

|

|

318 |

|

PresencePLUS Label Detection On Wire Spools PresencePLUS Label Detection On Wire Spools

|

전기전자, 기계, 화학

|

2003-02-19

|

1138

|

|

|

317 |

|

PresencePLUS Inspection of Spray Bottle Mechanism PresencePLUS Inspection of Spray Bottle Mechanism

|

전기전자, 기계, 화학

|

2003-02-19

|

1024

|

|

|

316 |

|

PresencePLUS Grease Presence Verification PresencePLUS Grease Presence Verification

|

전기전자, 기계, 화학

|

2003-02-19

|

1099

|

|

|

315 |

|

PresencePLUS Flaw Detection PresencePLUS Flaw Detection

|

전기전자, 기계, 화학

|

2003-02-19

|

1315

|

|

|

314 |

|

PresencePLUS Filter Orientation Check PresencePLUS Filter Orientation Check

|

전기전자, 기계, 화학

|

2003-02-19

|

1132

|

|

|

313 |

|

PresencePLUS Drive Shaft Orientation Inspection PresencePLUS Drive Shaft Orientation Inspection

|

전기전자, 기계, 화학

|

2003-02-19

|

1086

|

|

|

312 |

|

PresencePLUS Date/Lot Code Presence Verification PresencePLUS Date/Lot Code Presence Verification

|

전기전자, 기계, 화학

|

2003-02-19

|

1038

|

|

|

311 |

|

PresencePLUS Correct Bottle Cap Verification PresencePLUS Correct Bottle Cap Verification

|

전기전자, 기계, 화학

|

2003-02-19

|

1052

|

|

11

|

|

센서허브넷 소개

센서허브넷 소개  Sitemap

Sitemap