|

| ㆍ작성일 |

2003-02-22 |

| ㆍ첨부#2 |

1045875020.bmp

(0KB) (Down:3) 1045875020.bmp

(0KB) (Down:3)

|

| ㆍ응용분야 | 전기전자, 기계, 화학 |

|

ㆍ추천: 0 ㆍ조회: 1758

|

|

|

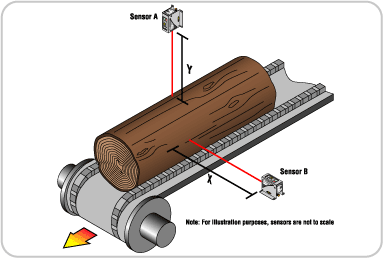

LT3 Log Profiling

LT3 Log Profiling

The LT3 Sensors are placed above and to one side of the log conveyor. They are placed approximately 2 meters from the log's surface, safely out of the way to prevent damage to the sensors, but well within the sensor's operating range. Each log is positioned between raised tracks in the conveyor, in effect centering it in a "trough." Each sensor sends a signal to a PLC, representing the distance from the sensor to the surface of the log. The PLC then calculates the log's diameter, based on the known distances to each sensor. If the logs can not be centered on the conveyor, a third LT3 sensor may be mounted opposite to sensor B to determine the log's width.

Objective:

To detect and calculate the diameter of each log as it passes on a conveyor belt, in order to optimize the milling of the log

Sensor Models:

Two LT3 diffuse-mode sensors with analog/discrete outputs

자료출처 : BANNER

|

| 번호 |

|

글 제 목 |

응용분야 |

작성일 |

조회 |

|

365 |

|

MINI-ARRAY Log Diameter Profiling MINI-ARRAY Log Diameter Profiling

|

전기전자, 기계, 화학

|

2003-02-22

|

2743

|

|

|

364 |

|

MINI-ARRAY High Resolution 3D Box Profiling MINI-ARRAY High Resolution 3D Box Profiling

|

전기전자, 기계, 화학

|

2003-02-22

|

2463

|

|

|

363 |

|

LT3 Log Profiling LT3 Log Profiling

|

전기전자, 기계, 화학

|

2003-02-22

|

1758

|

|

|

362 |

|

BEAM-ARRAY Paint Profiling BEAM-ARRAY Paint Profiling

|

전기전자, 기계, 화학

|

2003-02-22

|

1687

|

|

|

361 |

|

BEAM-ARRAY Log Diameter BEAM-ARRAY Log Diameter

|

전기전자, 기계, 화학

|

2003-02-22

|

1451

|

|

|

360 |

|

BEAM-ARRAY Box Profiling BEAM-ARRAY Box Profiling

|

전기전자, 기계, 화학

|

2003-02-22

|

1409

|

|

|

359 |

|

BEAM-ARRAY 3D Log Profiling BEAM-ARRAY 3D Log Profiling

|

전기전자, 기계, 화학

|

2003-02-21

|

1636

|

|

|

358 |

|

VTB Assembly Process Verification VTB Assembly Process Verification

|

전기전자, 기계, 화학

|

2003-02-21

|

1670

|

|

|

357 |

|

SL30 Gear Tooth Sensing SL30 Gear Tooth Sensing

|

전기전자, 기계, 화학

|

2003-02-21

|

1701

|

|

|

356 |

|

Q45U Ultrasonic Bin Fill-level Detection Q45U Ultrasonic Bin Fill-level Detection

|

전기전자, 기계, 화학

|

2003-02-21

|

1356

|

|

|

355 |

|

Q45U Roll Diameter Q45U Roll Diameter

|

전기전자, 기계, 화학

|

2003-02-21

|

1698

|

|

11

|

|

센서허브넷 소개

센서허브넷 소개  Sitemap

Sitemap